Copied from CASEY breaking news...

You are receiving this sponsor-paid news release as a Casey Research

subscriber. You may opt out of these news releases at any time, by clicking here. The distribution of this news does not constitute a recommendation or advice of any kind.

PRESS RELEASE

TSX Venture: MAT

OTCQX: MHREF

Matamec Announces Results of Positive Feasibility Study for Kipawa JV Heavy Rare Earth Project

Montreal, September 4, 2013 - Matamec Explorations Inc. (“Matamec”

or the “Company”) is pleased to announce the positive results of the

Feasibility Study (“FS”) for the Kipawa Joint Venture (“JV”) Heavy Rare

Earth Elements Project (“HREE”) (“the Project”). The FS was prepared

by Roche Ltd. and GENIVAR Inc. and supported by SGS Geostat and Golder

Associates Ltd. FS results show that the Project is technically and

economically feasible. An analyst’s conference call will be held today

at 10:00 a.m. ET. All numbers are reported in Canadian dollars unless

otherwise stated.

The goal of the Kipawa JV is to supply Toyota Tsusho Corp. (“TTC”)

with heavy rare earths such as dysprosium which is indispensable for

hybrid and electric vehicles. The JV partners are presently in

discussions and evaluating next steps to advance the project.

KIPAWA HREE PROJECT – FS FINANCIAL MODEL HIGHLIGHTS

|

Net Present Value (NPV10%) (Pre-Tax)

|

$260 million

|

Internal Rate of Return (IRR) (Pre-Tax)

|

21.6%

|

Revenue

|

$2.55 billion

|

EBITDA

|

$1.37 billion

|

CAPEX (initial)

|

$374 million

|

OPEX (annual)

|

$78.5 million

|

Payback Period (Pre-Tax)

|

3.9 years

|

Life of Mine (LOM)

|

15.2 years

|

Concentrate Production (annual avg.)

|

3,653 tonnes

|

- The Company is committed to bringing the IRR above 25% by

continuing to reduce the required CAPEX and OPEX, while optimizing the

overall recovery rate.

“Matamec has achieved a major milestone today in its 16-year history

as the feasibility study shows that the Kipawa project is technically

and economically feasible,” said Andre Gauthier, President and CEO of

Matamec. “The Company has strategically developed a solid business

plan which includes a moderate CAPEX and a manageable scale of annual

tonnage while ensuring the required environmental standards are met.

With the completion of the feasibility study results, we will continue

to work with the citizens of the Temiscamingue area to present the

economic benefits this project will create for the region. Matamec is

committed to building a sustainable organization with a particular focus

on green energy applications.”

ECONOMIC SUMMARY OF 2012 PEA VERSUS 2013 FEASIBILITY STUDY RESULTS

|

Metric

|

PEA Quantity March 2012

|

FS Quantity August 2013

|

Unit

|

| Total Mine Revenue |

2.822

|

2.548

|

$ billion |

EBITDA

|

1.68

|

1.37

|

$ billion |

Pre-production Capital Expenditures (initial)

|

315.8

|

374.4

|

$ million |

| Sustaining Capital Expenditures (incl. rehab.) |

38.2

|

37.7

|

$ million |

Additional Working Capital Requirement

|

9.9

|

11.2

|

$ million |

| Mine Rehabilitation Costs |

7.5

|

23.1

|

$ million |

| Total Operating Costs |

1.142

|

1.181

|

$ billion |

| Total Before-tax Cash Flow |

1.335

|

960

|

$ million |

| Total Basket Price after discount |

42.08

|

50.12

|

$ /kg |

|

HREO* Basket Price - concentrate |

-

|

39.79

|

$ /kg |

|

LREO** Basket Price - concentrate |

-

|

10.33

|

$ /kg |

| Economics (Pre-Tax) |

|

|

|

|

IRR |

36.9

|

21.6

|

% |

|

NPV @ (PEA 5%) (FS 6%) |

811

|

450

|

$ million |

|

NPV @ 8% |

606

|

344

|

$ million |

|

NPV @ 10% |

500

|

260

|

$ million |

|

NPV @ 12% |

-

|

191

|

$ million |

Payback Period

|

2.4

|

3.88

|

years |

| Economics (After-Tax) |

|

|

|

|

IRR |

-

|

16.8

|

% |

|

NPV @ (PEA 5%) (FS 6%) |

-

|

257

|

$ million |

|

NPV @ 8% |

-

|

185

|

$ million |

|

NPV @ 10% |

-

|

128

|

$ million |

|

NPV @ 12% |

-

|

81

|

$ million |

Payback Period

|

-

|

4.12

|

years |

| Mining |

|

|

|

|

Mineral reserves |

19.00

|

19.77

|

millions of tonnes |

|

Production rate (ore) |

4,110

|

3,650

|

tonnes per day |

|

Life of Mine |

12.9

|

15.2

|

years |

| Total CAPEX (based on 3,653 tpa) |

86.50

|

102.57

|

$ /kg (+18%) |

| Total OPEX (based on 3,653 tpa) |

24.44

|

21.53

|

$ /kg (-13%) |

| Total Operating Costs |

24.44

|

21.53

|

$ /kg |

|

General and Administration

|

8.84

|

11.6

|

$ million per year

|

|

Mining |

16.61

|

18.1

|

$ million per year

|

|

Process |

58.35

|

48.7

|

$ million per year

|

| Total Recovery Rate*** |

81

|

70

|

% |

|

Heavy average |

-

|

74

|

% |

|

Light average |

-

|

65

|

% |

*HREO – Heavy Rare Earth Oxide (Sm, Eu, Gd, Er, Tb, Dy, Ho, Yb, Tm, Lu and Y).

**LREO – Light Rare Earth Oxide (Ce, La, Nd and Pr).

***Samples used for PEA represent only the Western part of the deposit whereas FS samples represent the whole deposit.

KIPAWA JV FEASIBILITY STUDY RESULTS HIGHLIGHTS

|

Environmental and Permitting Process

A complete environmental baseline study will be finalized by

fall 2013; Environmental and Social Impact Assessment is subjected to

the Canadian Environmental Assessment Agency, which will be

available Q1 2014. The project notice to begin the Federal

environmental permitting process was submitted before the end of Q1

2013 and the official application for the Certificate of

Authorization to the Provincial “Ministère du Développement durable,

de l’Environnement, de la Faune et des Parcs” (MDDEFP) is planned to

be submitted by winter 2014.

|

Social Acceptability

Since 2009, Matamec has been committed to engaging the

Temiscamingue communities to include and take into consideration

their concerns in the development of the Project.

|

Mineral Resource Estimates

Total measured and indicated resource now stands at 23.857

million tonnes at 0.407% Total Rare Earth Oxide (TREO) representing

88% of total resource.

|

Mineral Reserve

Mine – total projected ore tonnage is 19.8 million tonnes with a TREO diluted grade of 0.4105%.

|

Mining

Projected to produce an avg. 1.33 million tonnes of ore per

year (3,650 tonnes per day) and avg. stripping ratio of 0.94 with

15.2 years mine life (excluding pre-production period).

|

Metallurgical Plant Site

The final products of the process plant will be a chloride

concentrate of HREE and a concentrate of LREO. FS results show a

lower recovery compared to the PEA study, but it also shows that the

process is working for the entire ore body, and highlights where the

process has to be optimized in order to improve the recovery. From the

previous results, a new Master Composite of ore is ready for further

piloting planned for fall 2013 to improve the process.

|

PROJECT DEVELOPMENT – PLANNED NEXT STEPS

|

Milestone

|

Timeline

|

Second Pilot Plant

|

Fall 2013

|

Environmental and Social Impact Study

|

Q1 2014

|

Environmental Process – Federal and Provincial

|

Now to Q1 2015

|

Development of off-take agreement

|

2014

|

Financing CAPEX Process

|

2014

|

Detailed Engineering

|

2014 to mid-2015

|

Construction of Mine

|

Q1 2015 to Q4 2016

|

Start-up of Mining Operation

|

Q4 2016

|

Mr. Gauthier commented, “The Company will work with government

authorities to ensure that all required areas are covered to receive

environmental permits. We have assembled a highly qualified team who

are focused on identifying every risk possible to ensure the

environment is given the utmost respect and protected for future

generations. The Company will continue its outreach efforts with the

community which we have been developing over the past four years to

create greater comprehension and visibility for the project. We

welcome and value the concerns of the citizens of the Temiscamingue

region and look forward to working together in building a sustainable

plan.”

Additional Upside Opportunities for the Kipawa Mine Project

Matamec has identified a number of opportunities that have the potential to add additional value to the project.

- The second metallurgical pilot plant testwork should be

conducted in addition to the bench scale and first pilot plant testwork

conducted up to now. This second pilot plant testwork will be

important to confirm, prior to detailed engineering, final sizing of

some process equipment. For the time being overcapacities have been

built into the design, but it could be reduced during the detailed

engineering, pending the pilot plant results. The second pilot plant

will also help to confirm improvements in regards of recovery rates

since conservative numbers were used for the FS.

- It would be significant to consider some testworks to separate

individual Rare Earths (RE) to increase the value of the project.

- Depending on the RE market conditions, it will be important to

continue the evaluation of other LREE concentrates and HREE

concentrates production scenarios in order to optimize the IRR before

detailed engineering.

- In the future and when the project is well in progress, testwork

can be performed to evaluate the possibility to recovering zirconium

and other minor metal by-products in the RE mineralized zones and in the

syenite body.

- Mineral resources on the Kipawa deposit can be increased by verification of lateral and down dip extensions by drilling.

- From the last results in the FS it is known that there is the

potential room for improvement in the open pit design when entering the

detailed engineering phase.

Considering the above mentioned points, the Company strongly

believes it can achieve greater success with bringing the IRR above 25%

by only slightly reducing the CAPEX and OPEX while improving the

recovery.

Review of the FS Project Development Model

The FS covers all aspects of project development, including mining,

mineral concentration, hydrometallurgical processing and separation of

heavy and light rare earth as well as all related infrastructure.

Roche developed its capital and operating cost estimates from first

principle capital quotations, estimates from suppliers, manufacturers,

contractors and experience based on comparable operations in Canada and

abroad. The capital and operating cost estimates were completed to a

level consistent with an intended level of accuracy of ± 15%.

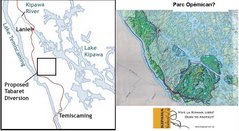

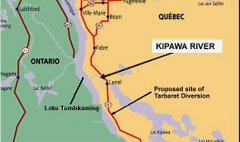

Project Location

The Kipawa deposit is located on the Zeus Property (see map below),

50 km east of the town of Temiscaming and 140 km south of

Rouyn-Noranda, Quebec. All claims are in good standing. Resources are

not subject to any third party royalties.

General Project Infrastructure Description

About 50 km of the Maniwaki road will be used to access the Kipawa

Project and share with public and other logging companies. Then a 4

km road will be built from the Maniwaki road to reach the process plant

site.

The Kipawa mining site will consist of the open pit mine, a waste

dump, a low grade stockpile and a high grade truck loading facility.

The mine equipment maintenance facility will also be located at the

mine site.

The metallurgical process plant site will be located south of the

mine site and south of the Kipawa River and a 10 km haul road will be

built to link the two sites. The metallurgical site will consist of the

ore process plant which will combine the crushing, grinding, magnetic

separation and hydrometallurgical circuits. At this site, there will

also be the administration and service building, a warehouse and the

assay laboratory.

There will be two dewatered tailing storage facilities; one storage

facility will be for the rejects of the magnetic separation process

located just by the process plant and one other storage facility for

the hydrometallurgical tailing located about 4 km south of the process

plant.

The employee’s parking and the main electrical sub-station will be

located near the town of Temiscaming. In the present study it is

planned to build a 44kV power line along the Maniwaki logging road to

provide power to the mining and processing facilities.

Geology, Mineralogy and Mineralization

The ore deposit is defined by three enriched horizons within the

“Syenite Complex”, which contains the fifteen rare earths elements

present. The Kipawa Alkaline Intrusive Complex consists of peralkaline

syenite and granite on average is less than 200 metres thick. It’s an

elongated, V-shaped body folded around a major southeast plunging

anticline. The west limb of this fold includes the Kipawa deposit,

which is entirely included within the lower syenite layer of the

complex. This mineralized syenite layer is a concordant sheet 50 to 80

meters thick that gently dips 20 to 30 degrees to the south-west. The

deposit outcrops over 1.4 km along strike with an additional outcrop

discovered 220 m to the north-west during the summer 2011 exploration

campaign.

Rare earth-yttrium-zirconium mineralization at the Kipawa deposit is

contained in medium grained silicate minerals. Grains are distinct and

generally well crystallized. Three minerals are presently considered

economical in the Kipawa deposit, namely eudialyte (a sodic silicate),

yttro-titanite/mosandrite (titanite silicate) and britholite (calsic

silico-phosphate) for the rare-earth and yttrium, with minor amounts of

apatite also present. Vlasovite/gittensite (sodic silicates) and

eudialyte (sodic silicate) are also considered for a potential

zirconium by-product.

Three vertically-stacked mineralized zones have been defined based

on their spatial characteristics: the Eudialyte (60% of existing rare

earth-yttrium resources), Mosandrite (25% of existing rare

earth-yttrium resources) and Britholite (15% of existing rare

earth-yttrium resources) zones. Despite their name, the different zones

contain a mix of the potentially economic minerals. The name simply

indicates the dominant REE mineral present in that zone. The main

Eudialyte zone, for example, consists of intermixed eudialyte (51%) and

mosandrite/yttro-titanite (39%) with trace britholite (10%). It sits

near the top of the syenite body and is not associated with any large

calco-silicate horizon. Note that all zones outcrop at surface.

The Kipawa deposit contains very low-levels of uranium and thorium

in the main REE-Zr mineralization. Average values of Th (193 ppm, or

0.019%) and especially U (22 ppm, or 0.002%): though higher than in the

surrounding rocks remains very low in the mineralized syenite portion

of the Kipawa deposit. Initial results suggest that most of the

thorium is contained in coarse-grained urano-thorite and ekanite

crystals, while the uranium is disseminated within said urano-thorite

and rare-earth minerals.

The terms “Mineral Resource” and “Mineral Reserve” are defined in the

CIM Definition Standards - For Mineral Resources and Mineral Reserves adopted by the CIM council of the Canadian Institute of Mining, Metallurgy and Petroleum.

Mineral Resources

The Kipawa Deposit resource are 10,478,000 tonnes at 0.46% TREO in

the measured category, 13,379,000 tonnes at 0.36% TREO in the indicated

category and 3,268,000 tonnes at 0.31% TREO in the inferred category.

The total of measured and indicated resource now stands at 23,857,000

tonnes at 0.41% TREO representing 88% of the total resource. These

results are at a 0.2% TREO cut-off and are not limited by an open pit.

The overall total tonnage is about 10% greater than the last resource

calculation (see press releases dated June 30 and July 7, 2011).

The Kipawa deposit’s mineral resource estimates were updated by SGS

Geostat. The drilling done since the 2011 PEA (see press release dated

January 30, 2011) totaling 14,293 m was included and permitted to

outline some measured resources for the first time in the history of

the project. The database now totals 293 drill holes totaling 24,571 m

and 13 trenches totalling 631 m. Historical Unocal holes are not in the

count and were not used for the estimates. The mineralized zones were

interpreted on vertical sections and meshed into volumes as per

industry standards. Ordinary Kriging was used to estimate the block

model with block size set at 10 m x 5 m x 5 m. The measured and

indicated resources required drill grids of 25 m and 50 m,

respectively. Resources extrapolated beyond 30 m of those drill grids

are considered inferred.

Mineral Reserves

By using SGS Geostat model, the mineral reserve for this FS was

prepared, estimated and supervised by Roche using a cut-off value of

$48.96/t with 5% dilution and a mining recovery of 95.2%. The Kipawa

open-pit design utilized a marginal (or milling) cut-off value of

$48.96/t and a break even cut-off value of $60.70/t. Included in the

reserves are 632,000 tonnes of low grade material lying between these 2

cut-offs values. This material will be sent to a low grade stockpile,

close to the mine site and will be processed at the end of operation

after mine depletion.

In-pit Mineral Reserves

|

Metric Tonnes

|

Proven (51.7% of the deposit)

|

10,219,000

|

Probable (48.3% of the deposit)

|

9,550,000

|

Total

|

19,769,000

|

|

|

Total Grade

|

|

Cerium (Ce2O3)

|

0.1195

|

Lanthanum (La2O3)

|

0.0588

|

Praseodymium (Pr6O11)

|

0.0146

|

Neodymium (Nd2O3)

|

0.0550

|

Samarium (Sm2O3)

|

0.0123

|

Europium (Eu2O3)

|

0.0015

|

Gadolinium (Gd2O3)

|

0.0119

|

Terbium (Tb4O7)

|

0.0022

|

Dysprosium (Dy2O3)

|

0.0147

|

Holmium (Ho2O3)

|

0.0032

|

Erbium (Er2O3)

|

0.0101

|

Thulium (Tm2O3)

|

0.0016

|

Ytterbium (Yb2O3)

|

0.0096

|

Lutetium (Lu2O3)

|

0.0013

|

Yttrium (Y2O3)

|

0.0943

|

TREO

|

0.4105

|

Design Basis

The Total Rare Earth Oxides (TREO) diluted grade is 0.4105%

including a dysprosium (Dy2O3) diluted grade of 0.0147%. The

calculation is using a dilution grade of 0.093% TREO. The recoveries

for each element vary from 65% to 74% for a TREO average of 70% for the

10 main REO which are (La2O3, Ce2O3, Pr6O11, Nd2O3, Sm2O3, Eu2O3,

Gd2O3, Tb4O7, Dy2O3 and Y2O3). A total production of TREO is expected

to be 55,529 tonnes over the mine life. When the mine will be in full

production (year 2-15) an average of 3,760 tonnes per year of TREO will

be produced.

Mining

The mine will produce an average of 1,332,250 tonnes of ore per year

(3,650 tonnes per day) and has an average stripping ratio (waste : ore

- without the overburden) of 0.94 with a mine life of 15.2 years. A

standard 55 tonne mining truck and shovel operation will bring the

drilled and blasted material out of the mine to their respective

destinations (waste dump, low grade stockpile or high grade loading

facility). Then the ore is transported by 40 tonne HD dump trucks to

the metallurgical plant site.

Processing

Once at the metallurgical plant site, the ore will be dumped into a

crusher dump hopper feeding a two stage crushing circuit. The crushed

ore will then be stored into a silo. The crushed ore will feed the

process plant at the rate of 3,650 tpd in a single stage grinding

circuit. A magnetic separation circuit will recover the rare earth as a

first concentrate. The reject from the mag-sep circuit will be pumped

to the dewatering circuit and transported by truck to the mag-sep

rejects storage facility located outside and nearby the process plant.

The magnetic rare earth concentrate will be sent into the regrind mill

followed by a thickening circuit and then to the hydrometallurgical

process (acid leaching, neutralization, impurities removal and the

final precipitation) will then produce the rare earth carbonate

concentrates. This hydromet concentrate will then be processed through a

purification circuit which will remove the last impurities and also

separate the h

eavies

from the lights. The final products of the process plant are a

concentrate of heavy rare earth and a concentrate of light rare earth.

The tailings produced from the hydrometallurgical process will be

pumped to a thickening facility located by the hydromet tailings

storage facility (TSF). The solids will be dewatered in few steps using

different technologies and then transported by truck and disposed

mechanically into the TSF. This TSF is thus believed to be subject to

progressive restoration throughout the mine life. Then the final

section is to be restored at the end of the mine life as well as the

other sites with varying infrastructures. The hydromet tailing storage

facility will require further investigation and design work as the

project advances into the next stages.

A total of 10 MW will be needed to power both the mine site and the

metallurgical site and will be provided by a new power line to be

connected to the Hydro-Quebec network.

In 2010, testwork at SGS Canada Inc. in Lakefield (Ontario) was

directed toward examining a known recovery process employing aggressive

conditions for extraction of rare earth elements

(acid baked leaching).

By early 2011, it had become evident that much less aggressive

conditions than anticipated were possible for the extraction of the

particular minerals present in the Kipawa ore

(room temperature leaching); this allowed a substantial improvement in simplifying the projected process plant design.

The present study is based on metallurgical test work results dating

prior to June 1, 2013. A pilot plant was performed during the summer

of 2012 with a Composite of ore taken from a bulk sample coming from

surface trenches. Then a series of variability samples were taken from

trenches and core samples from 18 large caliber drill holes in order to

make eight (8) Composites and also a Global Composite in order to

verify if the process was valid for the entire ore deposit. Results

showed lower recovery compared to the PEA study but it also showed that

the process works for the entire ore body and also where the process

needs to be optimized in order to improve the recovery.

From these previous results, a new Master Composite representing the

ore body is ready for further piloting which is planned for the fall of

2013, to further improve the ore processing plant.

ANNUAL OPERATING SUMMARY

|

Production

|

Unit

|

Year -1

|

Year 1

|

Year 2 to 15 (avg.)

|

Year 15.2

|

| Reserve mined |

Mt

|

0.022

|

0.870

|

1.348

|

0.000

|

Waste mined

|

Mt

|

0.468

|

0.928

|

1.233

|

0.000

|

Strip Ratio (waste : ore)

|

|

|

1.1

|

0.9

|

|

| Tonnes processed |

Mt

|

0.000

|

0.884

|

1.332

|

0.232

|

| Overburden |

Mt

|

1.328

|

0.000

|

0.000

|

0.000

|

|

|

|

|

|

|

Mixed REE concentrate

|

t

|

0

|

2,657

|

3,759

|

250

|

Mixed LREE concentrate

|

t

|

0

|

1,507

|

2,203

|

146

|

Mixed HREE concentrate

|

t

|

0

|

1,150

|

1,556

|

104

|

ANNUAL PRODUCTION REE LIGHT AND HEAVY CONCENTRATES (t)

|

REO

|

Year 1

|

Year 2-15 (avg.)

|

Year 15.2

|

Year 1-15.2 (avg.)

|

| Light Concentrate |

|

|

|

|

| Cerium (Ce2O3) |

727

|

1,049

|

69

|

1,018

|

| Lanthanum (La2O3) |

337

|

541

|

36

|

523

|

| Praseodymium (Pr6O11) |

94

|

131

|

9

|

127

|

| Neodymium (Nd2O3) |

349

|

482

|

33

|

469

|

| Heavy Concentrate |

|

|

|

|

| Samarium (Sm2O3) |

83

|

113

|

8

|

110

|

| Europium (Eu2O3) |

11

|

15

|

1

|

14

|

| Gadolinium (Gd2O3) |

83

|

115

|

7

|

112

|

| Terbium (Tb4O7) |

16

|

22

|

1

|

21

|

| Dysprosium (Dy2O3) |

106

|

144

|

9

|

141

|

| Holmium (Ho2O3) |

24

|

32

|

2

|

31

|

| Erbium (Er2O3) |

73

|

97

|

7

|

95

|

| Thulium (Tm2O3) |

11

|

14

|

1

|

14

|

| Ytterbium (Yb2O3) |

62

|

81

|

7

|

79

|

| Lutetium (Lu2O3) |

7

|

9

|

1

|

9

|

| Yttrium (Y2O3) |

674

|

913

|

60

|

890

|

Capital Cost Expenditures (CAPEX)

The capital cost estimate covers the development of the mine, ore

processing facilities and infrastructure required for the Kipawa HREE

project based on the application of standard methods of achieving a

feasibility study with an accuracy of ± 15%. The capital costs have been

estimated at $374.4 million, of which $257.99 million are direct costs

and $67.56 million are indirect costs such as engineering,

procurement, construction management, owner’s costs and an overall 15%

contingency cost of $48.83 million as outlined below:

Capital Cost Items

|

Cost

(Million $ CAD)

|

| Off-Site Installation near Temiscaming town |

|

Main Sub-Station / Hydro-Quebec Power / Parking

|

9.76

|

| Inter-Site Services |

|

| Power line 44kV / Communications / Part of Access road |

13.35

|

| Mine Site |

|

| Mining Equip / Pre-Prod./ Roads / Shop / …and other |

41.92

|

| Processing Plant Site |

|

Support Infrastructures

|

23.27

|

Process Plant

|

137.21

|

Fresh Water Supply

|

4.79

|

Tailing Storage Facilities / Pipelines / Effluent treatment

|

27.69

|

Plant Site Sub Total

|

192.96

|

|

|

Total Direct Costs

|

257.99

|

Total Indirect and Owner’s Costs

|

67.56

|

Overall Contingency (15%)

|

48.83

|

Total Costs

|

374.4

|

Operating Cost Expenditures (OPEX)

The operating cost estimate was made for each step and compiled by

Roche. The operating cost for the Matamec Kipawa operation covers

mining, ore transportation, ore processing, tailings and water

management, general and administration fees as well as infrastructure

and services. The project operating cost estimate is based on the

following main parameters:

- Tonnes of mineralized rock and waste mined per year: 2.5 million;

- Tonnes of mineralized rock milled per year: 1.3 million;

- Tonnes of mixed HRE concentrate: 1,516 tpa;

- Tonnes of mixed LRE concentrate: 2,137 tpa;

- Total manpower required for operation: 229 employees.

The overall operating cost for the Project is estimated at $78.5 million per year or $21.53/kg mixed TREO concentrate

. A summary of the operating costs for the project is shown below:

|

Unit |

Average

|

| Net Metal Return (NMR)* |

$ /kg TREO

|

46.97

|

| Mining |

$ /kg TREO

|

4.97

|

| Processing** |

$ /kg TREO

|

13.35

|

| G&A |

$ /kg TREO

|

3.18

|

| Cash Costs |

$ /kg TREO

|

21.53

|

Production of mixed contained Total Rare Earths concentrate

|

tpa

|

3,653

|

*NMR = Grade x Recovery x Revenue

|

**Processing includes tailings management costs

|

Market Study

The Rare Earth Elements (REEs) are typically defined as the fifteen

lanthanide elements including yttrium and scandium; they form a group

of technology enabling materials that are critical inputs for a wide

range of everyday consumer products as well as a large number of

cutting edge technologies. Strong magnetic, optical, electronic and

catalytic properties have made certain rare earth compounds

indispensable to a substantial portion of global industry, including

but not limited to the automotive, consumer electronics, medical

equipment and green technology sectors.

The demand for heavy rare earth materials is expected to benefit

from strong growth, particularly in the case of dysprosium, terbium and

yttrium, which are likely to realize swiftly expanding consumption

from both the permanent magnet and phosphor powder sectors. The

permanent magnet sector (neodymium and dysprosium and to a lesser

degree terbium) is generally forecasted to realize strong gains in

annual consumption through the entirety of the next seven years. The

combination of tightening Chinese supply along with growing demand

suggests terbium, dysprosium and several other HREEs will see

appreciating price levels. Though demand for yttrium is expected to

expand.

The Rare Earth Oxide prices used for the economic evaluation are

based on a contracted market survey by Asian Metals (one of world’s

largest metallurgical information providers) in conjunction with

discussions with key industrial end-users which were important in

defining the forecasted final prices of each rare earth oxide. Other

sources consulted for review of the historical pricing data were

websites and reports from Metal Pages, Roskill Information Service

Limited and Industrial Minerals.

REO PRICES – 2016 FORECAST

|

Rare Earth Oxides

|

|

FS Market Price Ex-Works

Mine-Site (US$/kg REO)

|

Refining Cost (%)

|

REO Price* Ex-Works Mine-Site

(US$/kg REO)

|

Quantity Sold LOM (est.)

(t REO)

|

| Cerium |

Ce

|

$5.90

|

30

|

$4.13

|

15,479

|

| Lanthanum |

La

|

$5.95

|

30

|

$4.17

|

7,952

|

| Praseodymium |

Pr

|

$75.40

|

30

|

$52.78

|

1,930

|

| Neodymium |

Nd

|

$75.00

|

30

|

$52.50

|

7,132

|

| Samarium |

Sm

|

$6.85

|

30

|

$4.80

|

1,679

|

| Europium |

Eu

|

$1,100.00

|

30

|

$770.00

|

215

|

| Gadolinium |

Gd

|

$59.40

|

30

|

$41.58

|

1,696

|

| Terbium |

Tb

|

$1,076.00

|

30

|

$753.20

|

321

|

| Dysprosium |

Dy

|

$713.00

|

30

|

$499.10

|

2,137

|

| Holmium |

Ho

|

$53.60

|

40

|

$32.16

|

474

|

| Erbium |

Er

|

$63.60

|

40

|

$38.16

|

1,063

|

| Thulium |

Tm

|

$1,200.00

|

40

|

$720.00

|

32

|

| Ytterbium |

Yb

|

$56.70

|

40

|

$34.02

|

555

|

| Lutetium |

Lu

|

$1,400.00

|

40

|

$840.00

|

55

|

| Yttrium |

Y

|

$29.40

|

30

|

$20.58

|

13,522

|

*REO price after deduction of refining and transport – Ex-works Matamec plant-site

|

Furthermore, the refining cost to reach 99.9% oxides or even higher

purity levels was not evaluated within the FS since refining was not

considered in the scope of the FS. It was decided that since the

forecasted prices are for 99.9% (min.) pure, individual oxides and

Matamec will be producing two mixed Rare Earths concentrates; a mixed

light rare earth concentrate that will contain the following REE’s: Ce,

La, Nd and Pr. With the second product, a mixed heavy rare earth

concentrate that will contain the elements of: Sm, Eu, Gd, Er, Tb, Dy,

Ho, Yb, Tm, Lu and Y. The projected selling prices for the

concentrates will be based on their contained oxide pricing and will be

reduced by a refining factor of 30% for the majority of the Rare

Earths, but 40% for the REE’s: Ho, Er, Yb, Tm and Lu. The higher

discount was applied considering that these materials would require

more costs associated to process them due to the higher degree of

purity that is required by the

ir

associated end uses. It is considered that the respective discounts

will cover all logistical costs for the material to be shipped to their

intended point of separation.

The Project is subject to a joint venture agreement (the “JVA”)

between Matamec and Toyotsu Rare Earth Canada Inc. (“TRECan”), a

subsidiary of TTC (see press release dated July 12, 2012 for more

details on the JV and the JVA). As at the date hereof, Matamec holds a

51% and TRECan a 49% interest in the Project (see press release dated

August 8, 2013). The JVA contains a provision under which TTC shall

become the off taker of the production from the Project, under the

terms and conditions set out in the JVA and in the off-take agreement

to be negotiated and executed by the parties. Negotiations to convert

the agreement into contractual volumes will follow the completion of the

FS. TRECan is a well-recognized strategic partner that has funded

$16.0 million to Matamec to complete the FS.

ECONOMIC ASSUMPTIONS

|

Rare Earth Oxides

|

PEA Market Price Forecast

(FOB China 2016 US$/kg REO)

|

FS Market Price Forecast

(Ex-Works Mine-Site US$/kg REO)

|

Quantity Sold per year (avg. est.) (t REO)

|

Est. Revenue LOM** ('000's)

|

| Cerium (Ce2O3) |

$5.00

|

$5.90

|

1,018.4

|

$63,926

|

| Lanthanum (La2O3) |

$10.00

|

$5.95

|

523.2

|

$33,120

|

| Neodymium (Nd2O3) |

$75.00

|

$75.00

|

469.2

|

$374,453

|

| Praseodymium (Pr6O11) |

$75.00

|

$75.40

|

127.0

|

$101,886

|

| Samarium (Sm2O3) |

$9.00

|

$6.85

|

110.5

|

$8,049

|

| Europium (Eu2O3) |

$500.00

|

$1,100.00

|

14.1

|

$165,486

|

| Gadolinium (Gd2O3) |

$30.00

|

$59.40

|

111.6

|

$70,521

|

| Terbium (Tb4O7) |

$1,500.00

|

$1,076.00

|

21.1

|

$241,636

|

| Dysprosium (Dy2O3) |

$750.00

|

$713.00

|

140.6

|

$1,066,608

|

| Holmium (Ho2O3) |

$65.00

|

$53.60

|

31.2

|

$15,246

|

| Erbium (Er2O3) |

$40.00

|

$63.60

|

70.0

|

$40,565

|

| Thulium (Tm2O3)* |

-

|

$1,200.00

|

2.1

|

$22,824

|

| Ytterbium (Yb2O3)* |

-

|

$56.70

|

36.5

|

$18,870

|

| Lutetium (Lu2O3) |

$320.00

|

$1,400.00

|

3.6

|

$46,496

|

| Yttrium (Y2O3) |

$20.00

|

$29.40

|

889.6

|

$278,292

|

Exchange Rate (CAD $/US $)

|

-

|

1.0 / 1.0

|

|

|

Discount Rate (%)

|

8%

|

10%

|

|

|

*At PEA, no value was attributed to Tm and Yb because no prices were available at date of publication.

|

**Est. Revenue LOM is

calculated from the (Price After Refining x Quantity Sold LOM) –

Quantity Sold is rounded to nearest tonne (see table pg. 11).

|

Economic Analysis

An economic/financial analysis of the project has been carried out

using a cash flow model. The model is constructed using annual cash

flow in constant money terms (second quarter 2013). No provision is

made for the effects of inflation. As required in the financial

assessment of investment projects, the evaluation is carried out on a

so called “100% equity” basis, i.e. the debt and equity sources of

capital funds are ignored.

TECHNICAL ASSUMPTIONS |

Item

|

Base Case Value

|

Unit

|

|

Total Ore Mined

|

19.77

|

M tonnes

|

|

Processing Rate

|

1.332

|

M tonnes / year

|

|

Life of Mine

|

15.2

|

years

|

|

Average Combined Process Recovery

|

70

|

%

|

|

Average Mining Cost

|

7.03

|

($ / tonne mined)

|

|

Average Processing Cost

|

36.57

|

($ / tonne milled)

|

|

Average General & Administration Costs

|

8.71

|

($ / tonne milled)

|

|

Financial Model and Results

A capital cost breakdown by item provides a preliminary capital

spending schedule over a 2-year pre-production period. The total

pre-production capital expenditures are evaluated at $374.4 million,

excluding the working capital. The total sustaining capital requirement

is evaluated at $37.7 million which includes rehabilitation

expenditures. A working capital equivalent of 3 months of total annual

operating costs is maintained throughout the production period. Apart

from the first fills and spare parts included in the pre-production

capital expenditures, an additional working capital outlay of $11.2

million is required. The total operating costs are estimated at $1.181

billion for the life of the mine or an average of $58.9/tonne milled.

The financial results indicate a positive before-tax NPV of $260

million at a discount rate of 10%, a before-tax IRR of 21.6% and a

payback period of 3.88 years.

REVENUES AND EXPENDITURES

|

Item

|

Base Case

|

Unit

|

| Total Mine Revenue |

2.548

|

billions $ CAD

|

| Pre-production Capital Expenditures |

374.4

|

millions $ CAD

|

| Sustaining Capital Expenditures (Incl. Rehab.) |

37.7

|

millions $ CAD

|

| Additional Working Capital Requirement |

11.2

|

millions $ CAD

|

| Mine Rehabilitation Costs |

23.1

|

millions $ CAD

|

| Total Operating Cost |

1.181

|

billions $ CAD

|

| Total Before-tax Cash Flow |

960

|

millions $ CAD

|

| Before-tax NPV @ 10% |

260

|

millions $ CAD

|

| Before-tax NPV @ 8% |

344

|

millions $ CAD

|

| Before-tax NPV @ 6% |

450

|

millions $ CAD

|

| Before-tax IRR |

21.6

|

%

|

| Before-tax Payback Period |

3.88

|

years

|

| Total After-tax Cash Flow |

602

|

millions $ CAD

|

| After-tax NPV @ 10% |

128

|

millions $ CAD

|

| After-tax NPV @ 8% |

185

|

millions $ CAD

|

| After-tax NPV @ 6% |

257

|

millions $ CAD

|

| After-tax IRR |

16.8

|

%

|

| After-tax Payback Period |

4.12

|

years

|

Sensitivity Analysis

A sensitivity analysis has been carried out on the base case

scenario described above to assess the impact of changes in REE market

prices, total pre-production capital costs and operating costs on the

project’s NPV @ 10% and IRR. Each variable was examined independently.

An interval of ±30% with increments of 10% were used for all three

variables. The project’s before-tax viability is not significantly

vulnerable to the under-estimation of capital and operating costs,

taken independently. The net present value is more sensitive to

variations in operating expenses. As expected, the NPV is most

sensitive to variations in REE prices, followed by operating costs and

by capital costs.

Environment, Permitting and Social Acceptability

Environment and Permitting

Matamec has always been proactive and has respected the rules outlined by the different government authorities.

After the first drilling campaign outlined a good quality deposit

(2009), Matamec decided to begin a baseline study of the territory

around the deposit. Enviréo Conseil, an independent firm from

Rouyn-Noranda, Quebec, was hired to perform the study of water, fish,

aquatic plants and mud samples which were taken from 5 sites, instead

of the 3 recommended by regulation.

Then in spring 2012, Matamec hired the firm Golder Associates Ltd to

complete the baseline study that was started two years before and also

to perform an Environmental and Social Impact Assessment which is

planned to be completed by Q1 2014.

A comprehensive program of geochemical characterization has been

conducted during the last year in order to classify all the varying

rock types to be mined, the ore, the overburden and also all the

different waste and residue to be generated by the mine and process

operation. The waste rock, ore, and magsep tailings are classified as

non-acid generating. The hydromet tailings sample analyzed is

classified as acid generating based on its high sulfur content but all

sulphur occurs as sulphate which is already oxidized and therefore not

expected to generate acidity in the future.

Further radiological analyses of leachates were carried out for

safety purpose and as required under Directive 019 of the MDDEFP to

evaluate the level of risk associated with possible leaching of

radiogenic parameters from mine wastes, magnetic separation rejects and

hydrometallurgical tailings. None of the samples analysed are

classified as high risk waste based on radionuclide analyses in

leachate. Analyses were also done on the solids themselves and so far

the hydrometallurgical tailings are classified as potentially

radiogenic, but manageable. The implementation of proper management

programs in regards to radioactive elements will ensure the safety of

the workers and of the population during operation and after the mine

closure. Furthermore, additional geochemical analysis will be conducted

before detailed engineering in order to determine all the final

classification and design parameters for the infrastructures related to

the tailings management.

Hydrological and hydrogeological studies were carried out as well.

From the collected information, a water management plan has been put

together and will be optimized at further stages in the project. A

site-wide water quality evaluation study is underway to determine

future water treatment needs at the mine site and hydrometallurgical

waste storage sites.

From all the information collected during the FS, it was decided to

proceed with dewatered tailings even if it is much more expensive in

operating costs in order to minimize environmental risks related to the

tailings management. It will also allow the operator to consider

progressive site restoration during mine operation.

The mining lease was filed before the end of March 2012. The

project notice to begin the Federal environmental permitting process

was submitted before the end of Q1 2013. The restoration plan and

environmental impact study commenced at the beginning of May 2012 and

are still ongoing but are well advanced. The official application for

the Certificate of Authorization to the MDDEFP is planned to be

submitted by winter 2014.

Social Acceptability

Since 2009, the Matamec Team is making social acceptability a

priority for the Kipawa Project, as well, the Company is committed to

being visible to the people in the region as a socially responsible

neighbour.

In March 2012, our regional office was opened in downtown

Temiscaming, creating visibility and allowing easy accessibility to

information for people in the region. Regular meetings and discussions

are held with the First Nations Communities, with the signature of a

Memorandum of Agreement with them. Under this agreement, the First

Nations communities completed their own cultural impact assessment

study describing the past and current traditions and resources used in

the project area. They also completed their socio-economic baseline

report for the project. These studies will contribute to the

preparation of the environmental effects assessment of the Kipawa

project.

There is an open and constant communication between the Matamec team

and the citizens. Public information meetings are held throughout the

region, highlighting our commitment to dialogue and opportunities for

questions about the project.

We strive to understand all stakeholders concerns and maintain our

strategy of transparency executed through active and consistent

communication.

NI 43-101 Disclosure

The technical information in this news release has been prepared in

accordance with Canadian regulatory requirements by the following

persons, or under the supervision of, all of whom are independent

Qualified Persons as set out in National Instrument 43-101 Standards of

Disclosure for Mineral Projects ("NI 43-101").

Qualified Person

|

Consulting Firm

|

Contribution

|

| Guy Saucier, Eng. |

Roche Ltd. |

Project Supervisor |

| Yann Camus, Eng. |

SGS Geostat |

Mineral Resource |

| Pierre Casgrain, Eng. |

Roche Ltd. |

Mining |

| Al Hayden, P. Eng. |

EHA Engineering Ltd. |

Metallurgy |

| Eric Poirier, Eng. |

GENIVAR Inc. |

Infrastructure |

| Michel Mailloux, Eng. |

Golder Associates |

Environment |

| Marc Rougier, Eng. |

Golder Associates |

Geotechnical |

| Mayana Kissiova, Eng. |

Golder Associates |

Tailings & Water Management

|

| Valerie Bertrand, P. Geo. |

Golder Associates

|

Geochemistry

|

| Gaston Gagnon, Eng. |

SGS Geostat |

Marketing |

| Michel Bilodeau, Eng. |

Roche Ltd. |

Financial Model |

The Mineral Resource and Mineral Reserve estimates set out in this news release were classified according to the

CIM Definition Standards - For Mineral Resources and Mineral Reserves (as adopted by CIM Council in November 2010).

Readers are advised that Mineral Resources not included in Mineral

Reserves do not demonstrate economic viability. Mineral Resource

estimates do not account for mineability, selectivity, mining loss and

dilution. These Mineral Resource estimates include Inferred Mineral

Resources that are normally considered too speculative geologically to

have economic considerations applied to them that would enable them to

be categorized as mineral reserves. There is no certainty that Inferred

Mineral Resources will be converted to Measured and Indicated

categories through further drilling, or into Mineral Reserves, once

economic considerations are applied.

Technical information in this press release was reviewed and adopted

by Bertho Caron, VP Project Development & Construction (Eng.) and

Aline Leclerc, VP Exploration (Geo.), Matamec’s Qualified Persons for

this press release.

The full feasibility study, prepared in accordance to the NI 43-101

compliant technical report, will be filed under Matamec Explorations’

profile on SEDAR at www.sedar.com within 45 days.

Conference Call

Matamec will be hosting an analyst conference call on

Wednesday, September 4, 2013 at

10:00 a.m. (Eastern Time). Participants may join the call by dialing toll free

1-800-381-7839 or 1-416-981-9000. A live webcast of the call will be available through our website at:

www.matamec.com. A copy of the presentation will be available on our website one hour prior to the webcast.

A taped replay of the conference call will be available starting

that same day at 12:00 p.m. ET by dialing 1-800-558-5253 or

416-626-4100 and entering passcode 21667794#, until September 18 at

midnight.

About Matamec

Matamec Explorations Inc. is a junior mining exploration company

whose main focus is in developing the Kipawa HREE deposit with TRECan.

In parallel, the Company is exploring more than 35 km of strike

length in the Kipawa Alkalic Complex for rare

earths-yttrium-zirconium-niobium-tantalum mineralization on its Zeus

property. Since 2008, Matamec discovered many potential showings.

Particularly, it drilled the PB-PS Zone in the fall of 2012 and

identified similar Eudialyte-Mosandrite/Yttro-Tantanite/Britholite

associated mineralization founded at the HREE Kipawa Deposit. This type

of mineralization is presently known over 200 metres long and it opens

laterally and at depth. The Company plans to drill these extensions

later this year.

The Company is also exploring for gold, base metals and platinum

group metals. Its gold portfolio includes the Matheson JV property

located along strike and in close proximity to the Hoyle Pond Mine in

the prolific gold mining camp of Timmins, Ontario. In Quebec, the

Company is exploring for lithium and tantalum on its Tansim property

and for precious and base metals on its Sakami, Valmont and Vulcain

properties.

Cautionary Statement Concerning Forward-Looking Statements

This news release contains “forward-looking information” within

the meaning of Canadian Securities legislation. Generally,

forward-looking statements can be identified by the use of

forward-looking terminology such as “scheduled”, “anticipates”,

“expects” or “does not expect”, “is expected”, “scheduled”, “targeted”,

or “believes”, or variations of such words and phrases or state that

certain actions, events or results “may”, “could”, “would”, “might” or

“will be taken”, “occur” or “be achieved”. Forward-looking statements

contained herein include, without limitation, statements relating to

mineral reserve estimates, mineral resource estimates, realization of

mineral reserve and resource estimates, capital and operating costs

estimates, the timing and amount of future production, costs of

production, success of mining operations, the ranking of the project in

terms of cash cost and production, permitting, economic return

estimates, power and storage facil

ities,

life of mine, social, community and environmental impacts, rare metal

markets and sales prices, off-take agreements and purchasers for the

Company’s products, environmental assessment and permitting, securing

sufficient financing on acceptable terms, opportunities for short and

long term optimization of the Project, and continued positive

discussions and relationships with local communities and stakeholders.

Forward-looking statements are based on assumptions management believes

to be reasonable at the time such statements are made. There can be

no assurance that such statements will prove to be accurate, as actual

results and future events could differ materially from those

anticipated in such statements. Accordingly, readers should not place

undue reliance on forward-looking statements. Although Matamec has

attempted to identify important factors that could cause actual results

to differ materially from those contained in forward-looking

statements, there may

be

other factors that cause results not to be as anticipated, estimated or

intended. Factors that may cause actual results to differ materially

from expected results described in forward-looking statements include,

but are not limited to: Matamec’s ability to secure sufficient

financing to advance and complete the Project, uncertainties associated

with Matamec’s resource and reserve estimates, uncertainties regarding

global supply and demand for rare earth materials and market and sales

prices, uncertainties associated with securing off-take agreements and

customer contracts, uncertainties with respect to social, community and

environmental impacts, uncertainties with respect to optimization

opportunities for the Project, as well as those risk factors set out in

the Company’s year-end Management Discussion and Analysis dated

December 31, 2012 and other disclosure documents available under the

Company’s profile at www.sedar.com. Forward-looking statements

contained

herein

are made as of the date of this news release and Matamec disclaims any

obligation to update any forward-looking statements, whether as a result

of new information, future events or results or otherwise, except as

required by applicable securities laws.

"Neither TSX Venture Exchange nor its Regulation

Services Provider (as that term is defined in the policies of the TSX

Venture Exchange) accepts responsibility for the adequacy or accuracy

of this release."

For further information please contact:

André Gauthier, President

Tel: (514) 844-5252

Email: info@matamec.com

Edward Miller, Director IR

Tel: (514) 844-5252 ext. 205

Email: edward.miller@matamec.com